Italy is rich in food and culture. I’m very fortunate that I was able to visit Parma, Italy in September of last year. While on my trip, I gained a deep appreciation for their food and culture. I feel that FLVS students and many others can gain useful insights from Italian cuisine, history and culture. Two unique delicacies that cannot be rivaled are produced in this region. These food products showcase Italian’s commitment and devotion to quality and freshness.

Parma is arguably Italy’s food capital. It’s where some of the most iconic Italian foods are made. Parma ham, also called prosciutto Crudo di Parma, is made in this region. It’s one of Parma’s crown jewels. These special types of hams are cured in salt for several weeks. Only hams that are cured in Parma are eligible to become Parma hams. However, not all hams cured in Parma pass the rigorous assessments necessary to become Parma hams. A prestigious consortium regulates Parma ham production. The consortium has only authorized 160 companies to produce Parma hams.

A Distinct Taste that Cannot Be Replicated: Parma Hams

Parma hams are shockingly simple. The four ingredients necessary to produce them are pigs born and bred in Italy, salt, air and time. In order to start the process of producing the hams, an experienced worker rubs sea salt into the meat. After that, the ham is refrigerated for seven days. Afterward, the hams are taken out of the fridge and excess salt is removed. With the excess salt removed, they add another thin coat of salt. This layer of salt remains on the ham for 15 to 18 days. The skilled professionals alter the temperature and humidity to ensure that the hams are absorbing the proper amount of salt. After the 15 to 18 days, hams are hung for about 80 days in special rooms. These rooms are closely monitored to ensure that they maintain the correct levels of temperature and humidity. Changes in these two factors could drastically alter the taste of the ham. After hanging for a while, the hams are transported to cellars. While they in these cellars, they are kept at room temperature.

The air in Parma is the unique factor that sets Parma ham apart from others. Every factory where Parma ham is produced has tall and closely set windows, so air can seep into the building. The hams are kept in these special cellars for approximately three months. At the end of this stage, the exposed surface of the hams has dried and hardened. The firm surfaces of the ham are rubbed down with a paste that consists of fat, salt and pepper. After the paste is applied, the hams are transported to another room to finish their curing processes.

In order to become Parma ham, a ham must be cured for at least 12 months. However many hams are cured for longer periods of time, and there’s no limit on how long a ham can be cured. However, surpassing the 12-month mark is very important for prospective Parma hams. This is because after they have spent 12 months curing, an individual from the consortium pays a visit to conduct important quality testing. They prick each ham in five key areas using a horse bone, then they analyze the aroma of the Parma hams after each prick. Hams that pass the test, are fire branded with the consortium’s official seal and become an official Parma ham. Those that fail the test can be sold, but, they are not Parma hams. Oftentimes, national brands package, produce and sell the hams that have failed the quality test. Parma hams have a distinct sweet and salty taste that cannot be replicated, and the labor-intensive process that goes into producing them reflects Italian’s commitment to quality and freshness.

The World’s Most Famous Cheese: Parmigiano-Reggiano

Another unique food product produced in Parma is Parmigiano-Reggiano. Italian’s strive for the same quality and freshness they maintain while producing Parma ham when producing what is arguably the world’s most famous cheese. You may think that Parmigiano-Reggiano is similar to the domestic parmesan that American’s are accustomed to, but don’t be fooled!

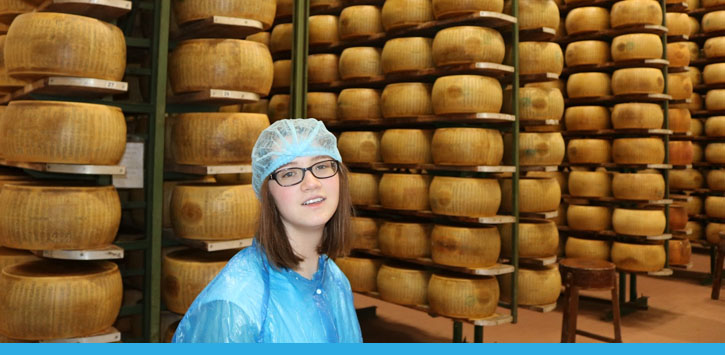

Parmigiano-Reggiano is much more nutty and complex than its domestic counterpart. The process of making this remarkable cheese is long and strenuous, yet beautiful at the same time. Parmigiano-Reggiano can only be produced in Parma as well as a few other select cities in northern Italy. Only 329 factories are certified to produce Parmigiano-Reggiano.

Wheels of Parmigiano-Reggiano are made from three ingredients. Cows milk from crows born and bred in Italy, salt and remnant. Remnant is an enzyme and it’s what gives the cheese its distinct salty and tangy flavor. The process and production of the cheese are regulated by a consortium; it is very similar to the consortium that regulates the production of Parma ham. Like Parma Ham, Parmigiano-Reggiano undergoes strict quality control assessments in order to become certified.

In order to make Parmigiano-Reggiano, fresh milk, one-day-old skim milk, certain good bacterias and enzymes are mixed together in a large vat. Next, a highly skilled employee will use a special instrument called a spino to manipulate the milk mixture so that curds form. Then, hot water is added to the cheese mixture to ensure harmful bacteria don’t ruin the final product. Adding the water changes the texture of the mixture, and cooks the milk. During the cooking process, the curds will sink down to the bottom of the vat. After approximately 45 minutes, a massive curd ball weighing about 220 pounds will form. Next, using linen cloth, workers lift the curd ball out of the vat. They use a huge knife to separate the ball into two pieces. Next, workers transfer both cheese balls into molds and linen cloths are wrapped around them. After this, the cheese wheels are tilted to one side and rest for a bit.

At approximately 8:00 PM, the cheese wheels are stenciled with special markings. These markings are how consumers can be sure they are purchasing authentic Parmigiano-Reggiano. Each cheese wheel is also given its own unique barcode id. This id contains important information about where and when a particular cheese wheel was produced. Four days later, the stencil is wiped off, and the cheese wheels are placed into giant brine baths. They stay completely submerged in these brine baths for 19 days. submerging the cheese wheels in the brine baths creates the hard cheese rind. After the cheese wheels are removed from the brine baths, they begin the aging process. They are transported to a special room and placed on shelves. They remain on these shelves undisturbed for approximately one year. After they pass the one year mark, an employee from the consortium comes to conduct the quality assessments. They tap the cheese wheels with a special instrument. Those that pass the assignment are branded with the consortium’s seal. After passing the quality assessment and being branded, the cheese wheels are ready to be sold. However, most of them set on the shelves for another year before becoming available to consumers.

Although the average aging process only lasts two years, cheese wheels can be aged for up to ten. Parmigiano-Reggiano that is aged for different amounts of time will have subtle flavor differences. Typically, the longer the cheese ages the more nutty and pungent it will become. Making Parmigiano-Reggiano is a truly unique art form, and consumers around the world can taste the difference that sets Parmigiano-Reggiano apart.

Appreciating the Artistry of Food

Today, not everyone thinks about what goes into the making of their food. To us, food serves only one purpose: to obtain the necessary nutrients in order to continue surviving. Many of us have to rush to dance, soccer, swimming, occupational therapy or a plethora of other activities. Out of habit, we put food into our bodies without much thought.

The most important lesson I learned from my trip to Parma was not how long Parmigiano-Reggiano is aged or just how much salt should be rubbed on a Parma ham. The most important lesson that I learned from my trip to Parma was to slow down and enjoy my food. I think about all the subtleties that went into making the product that I’m consuming. I would recommend that anyone reading this should do the same!

The good news is that one can appetite the subtleties of food while in Parma, Italy touring a cheese factory, or while at home in their living room during a pandemic. How or where someone learns this lesson is not an important factor, it’s the learning that’s key.

Photo credits: Chris Tidwell

Sources:

Great article, Morgan! 🙂

This is a great window into two sought after delicacies. Thanks for the interesting explanations. I now have more appreciation of both products and I do enjoy them often.

What an interesting article! I’ll never think of Parmesan cheeses the same again after your interesting details of how it’s produced. Thank you for sharing your food experiences. I felt like I was there in Parma with you learning about what’s involved in producing hams and cheese. As you suggested in your article, I’m going to slow down and enjoy my food and appreciate what went into making it.